In this article:

EVO™ electric diaphragm pump: ideas evolving into reality

EVO™ Series electric diaphragm pump: ARO® thus marks the latest step in the evolution of the sector.

With a ground-breaking innovation, the prestigious brand – a symbol of reliability in pumping technology for 100 years – turns the previous rules, filling a gap in the pump market.

We stand by them, as a long-standing partner and distributor of ARO® excellence in Italy.

The EVO™ Series electric diaphragm pump retains many of the advantages of the EXP Series – industry leading pneumatic diaphragm pumps – while combining them for the first time with features typical of other devices.

The result? A technology that combines the advantages of a traditional diaphragm pump with those of an electrically driven pump, radically solving the problem of high maintenance costs of process pumps. The EVO™ Series electric diaphragm pump combines previously unavailable features in a single pumping technology, ensuring safety, uninterrupted system operation and reduced operating costs.

This is the latest gift from ARO®’s engineers: the creation of a product that guarantees the coveted performance of existing technologies, while completely overcoming their limitations. This translates into zero maintenance costs and no production downtime.

This is a real evolution in the pumping sector that actually increases the productivity of installations in several areas.

The benefits are immediately apparent in the areas of chemical treatment, in wastewater treatment and in the manufacturing industry in general.

The solution to a big problem. A limitation overcome by offering the customer added value.

An important new milestone marked by Ingersoll Rand, with whom we have been sharing a growth path for 30 years based on the same values: quality and total dedication to the customer.

Tangible solutions in fluid handling that translate for ARO® into outstanding products and for Movingfluid into their distribution, always accompanied by qualified and responsible advice, able to shed light under the most difficult conditions.

Take your advantage over others:

How the world of pumping is changing today

The EVO™ Series electric diaphragm pump represents a technological revolution, without half measures.

While the market was previously divided into two main technologies, each with severe limitations, today the EVO™ Series electric diaphragm pump offers an ingenious synthesis of the positive performance of both, but with all their limitations removed.

In detail, this is what existed until yesterday:

- Electrically driven process pumps: they use fluid transmission systems according to a compression principle with mechanical systems: impellers, worm screws, rotors, vanes, gears. These methods, over time, cause inevitable abrasion to the parts involved in transmitting motion in contact with fluids.

Limits:

need for repeated maintenance over time, with high spare parts and running costs. Electrically driven process pumps require compulsory back-up pumps as well as disassembly and cleaning.

- Air-driven diaphragm pumps: unlike the previous ones, they require low maintenance costs and offer high resistance and efficiency.

Limits:

air drive has a high energy consumption. This makes it appropriate for intermittent and sporadic applications, but certainly inappropriate for process operations (24h 7/7).

Today, alongside ARO®, expectations have evolved into a definite response and unprecedented performance.

Do you want a diaphragm pump with the efficiency and control of other positive displacement pumps?

EVO™ pump: distinctive advantages

Before being launched on the market, the EVO™ electric pump was subjected to the most stressful wear tests: 20,000 hours (800 continuous days) of relentless testing under full load, in the toughest conditions, with a wide variety of materials.

Result? The EVO™ pump has demonstrated an exceedingly high level of resistance, superior to that of any other progressive cavity pump. A concrete response to the most stringent expectations.

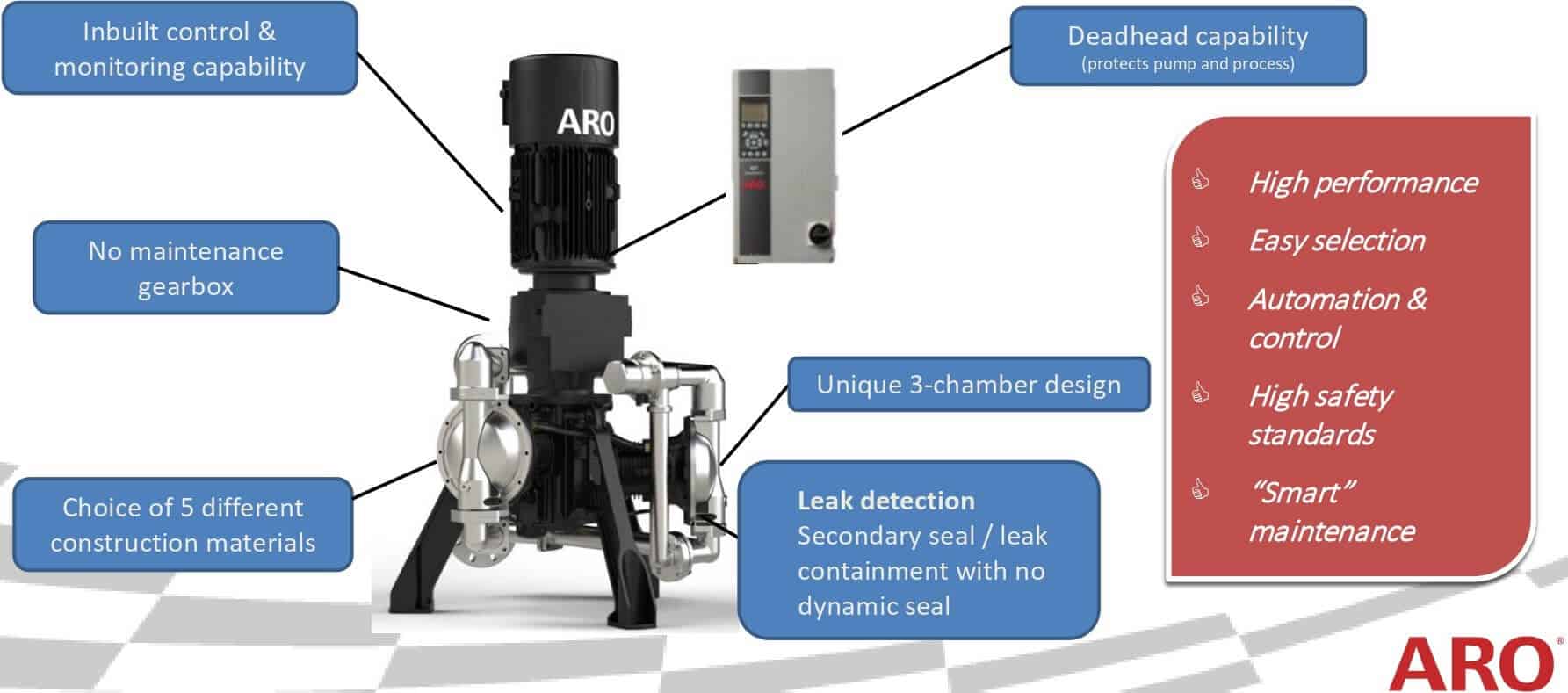

Without a doubt, the EVO™ Series is distinguished by:

Safety

The EVO™ pump provides protection in the event of no-load operation, including leak detection and containment.

How? A speed detecting encoder controls the slowing down of the motor, maintaining system pressure for a long time. The automated system allows the process to be restarted without priming. The pump can also be programmed to switch off automatically.

Built-in leak detection sensors allow you to detect diaphragm faults and shut down the pump to prevent leaks.

For added safety, there are also secondary seals to protect the actuation mechanism.

Performance

Its unique three-chamber concept means that pulsations are significantly lower than with conventional two-chamber electric diaphragm pumps.

Installation is also quite simple, as no base or shaft alignment is required. Thanks to its small footprint, the EVO™ Series pump fits easily into small operating spaces.

Check

Thanks to the integrated encoder and variable frequency drive, which are also included, the pump flow can be monitored and controlled according to process parameters such as flow, head, torque and more.

Productivity

Optimised flow rates + minimum pulsation and air consumption = maximum performance.

Versatility

The EVO™ Series electric pump is available in a wide range of materials – metals and technopolymers – compatible with different applications, making it suitable for use even in the presence of aggressive or abrasive fluids.

The distinct types of doors and interfaces available also allow the pump to be customised, which is essential for specific applications in original equipment manufacturing (OEM).

Care for the environment

The bolted construction, combined with the wide choice of construction materials, gives the EVO™ Series pump high resistance to chemicals, drastically reducing the risk of leakage.

Ease of maintenance

The modular design, reduced number of components and intuitive, fast repair kit minimise intervention time and costs.

You don’t believe it if you don’t see it with your own eyes?

EVO™ pump: technical specifications

Below is an overview of the product, highlighting some of the distinctive features and resulting benefits:

- Integrated encoder

- Maintenance-free gearbox

- Design without mechanical seals, preventing hazardous fluids from escaping into the environment

- Unique three-chamber design, resulting in less pulsation than traditional two-chamber pumps

- Made of five varied materials to handle the most aggressive and corrosive fluids

- Low-friction liquid transfer capability, resulting in optimal handling of abrasive, solid and corrosive materials, and dry running capability

- Self-priming

- Integrated control and monitoring capabilities

- PLC control option

- Available in two versions to suit different flow rates: 189 or 530 litres per minute

Specifications and performance

| Models | Maximum flow

(Lt/min.) |

Pressure

(BAR) |

Type |

Manufacturing materials |

| EP10X | 189 Lt/min. | Input: 0.7 bar

Output: 8.3 bar |

Standard and dangerous | Aluminium

Stainless steel Cast iron Polypropylene Conductive polypropylene |

| EP20X | 530 Lt/min. | Input: 0.7 bar

Output: 8.3 bar |

Standard and dangerous | Aluminium

Stainless steel Cast iron Polypropylene Conductive polypropylene |

Would you like to know all the technical features of the new EVO™ Series pump?

For the chemical industry, an added value not to be missed

Among the many sectors that can benefit from the market introduction of the latest ARO® innovation is the chemical industry.

An industry in which Italy excels, as reported by Federchimica Italia. With a production value of EUR 51 billion, Italy is the third largest chemical producer in Europe and tenth in the world.

But its importance is not limited to the size component. The chemical industry is characterised by significant research and technological innovation. A combination that brings significant multiplier effects on the whole economy in terms of improved productivity, competitiveness and environmental sustainability.

It is precisely the commitment to R&D (more than 180 million euros per year) that in many cases makes Italy the home of centres of excellence of global Groups for certain areas of chemistry or specific productions. It is no coincidence that almost 60% of the value of chemical production in our region is accounted for by foreign or national-controlled multinational companies.

A broad industrial base, where strong competitiveness is spreading: continuous research and experimentation to identify new production and technological solutions are essential to stand out.

In the fine chemicals and process market, the innovative EVO™ Series electric diaphragm pump is the perfect tool to make the leap to excellence, improving process quality and increasing productivity non-stop and without wasting valuable raw materials.

Efficiency, operational safety and optimal day-to-day operation are the added value with which ARO® validates its latest step towards process excellence, with a view to supporting people.

In the chemical industry, as in many others.

Would you like to test the new EVO™ Series electric diaphragm pump for yourself?

Book your demo now throughout Italy.

- airless painting [1]

- Alstom [1]

- ARO Ingersoll Rand [1]

- Automotive [8]

- Brembo [2]

- Case History [13]

- Cast iron brakes [1]

- Ceramic [2]

- Chemical [3]

- chemical mixer [1]

- Chemistry [2]

- Cleaning [1]

- cleaning industrial machinery [1]

- Dilution [1]

- Dosage [4]

- Dust [1]

- Extrusion [3]

- Finishing [1]

- Fluid handling [3]

- Fluids [2]

- Food [1]

- Freni in ghisa [1]

- Gases [3]

- Glue [2]

- Henkel [1]

- Industrial Painting [4]

- industrial tile painting [1]

- IVECO [1]

- Know-how [2]

- Körber Tissue [2]

- Lamborghini [2]

- Liquid paint [1]

- Liquids [6]

- LPR [1]

- Market news [4]

- mixing chemicals [1]

- Nikola [1]

- Oenology [2]

- Oil & Gas [1]

- Paint [2]

- Paper [2]

- Paper converting [1]

- Paper industry [2]

- Powder Coating [1]

- Powders [1]

- pump test bench [1]

- Raw material producer [1]

- Saipem [1]

- Spraying [5]

- Streparava [1]

- SuperSix [1]

- tile [1]

- tile painting [1]

- Tissue [3]

- Tissue converting [2]

- Toscotec [1]

- Trail [1]

- Transfer [7]

- Verniciatura industriale [3]

- vortex hydra [1]