In this article:

- A necessary evolution for even higher performance pumps

- Features of the new ARO metal electric diaphragm pump

- Advantages assured with the new ARO EVO 210 pump

- Bad luck is in the air: why not solve it now?

Eliminate the hassle (and cost) of compressed air with the new ARO electric double diaphragm pump

The fact that diaphragm pumps are used in the industrial sector for fluid handling is nothing new: these are valid and widespread solutions, which perform their task without any particular technical criticality. True, except for the fact that – to function – they need compressed air and, therefore, electricity. Lots of electricity.

So why not directly choose an electric pump that, using the same mechanism as the pneumatic version, makes you save in consumption, and also increases operating efficiency?

This is how the new ARO EVO 210 electric diaphragm pump came into being: reliable, compact and easy to handle, it replaces compressed air systems even in areas where they could not be used until now.

A necessary evolution for even higher performance pumps

The transfer and dosing of abrasive or corrosive liquids has long been solved through the diaphragm system. A system that is not abandoned, but now evolves thanks to the electric pumps manufactured by ARO® and distributed in Italy by Movingfluid. This is not new in the absolute sense: already a few years ago we successfully launched the ARO EVO Series™ pump, a top of the range pump for those with exceptional production requirements.

What was missing, however, was a solution suitable – in terms of cost, size and use – for standard industrial contexts in various sectors: chemical, pharmaceutical, ceramic, for companies engaged in mining or painting, in flexographic printing, in waste water treatment and in manufacturing in general.

With the new electric pumps of the EVO SeriesTM 200 family we have met the performance and savings expectations of this market segment, thus overcoming all the complexities associated with pneumatic pumps.

Features of the new ARO metal electric diaphragm pump

The first to come out of the entire series is a 1” metal electric pump, available for ordinary applications and with different configurations depending on the specific application: it can be made of aluminium, Teflon, stainless steel, etc. as is already the case with classic diaphragm pumps.

The new ARO pump combines the engineering of the compressed air pump with the proven technology of its “big sister” ARO®. In addition, it can be provided with ATEX certification.

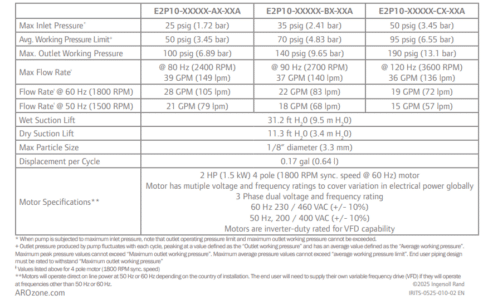

These, in brief, are the main characteristics:

The result? A robust, reliable and electrically driven diaphragm pump suitable for all continuous and prolonged process operations, designed for a pure industrial market.

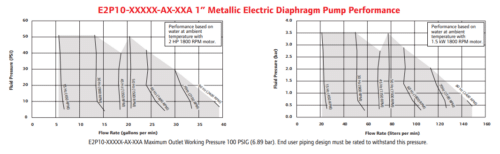

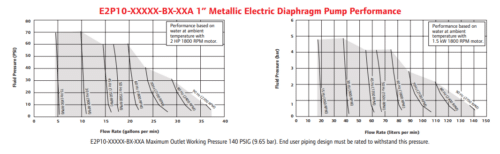

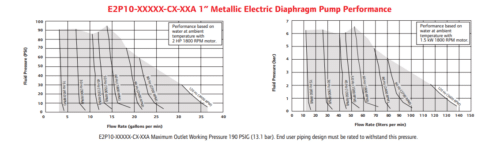

The performance curves give an even better idea of performance:

Advantages assured with the new ARO EVO 210 pump

Electricity has been the focus of attention of customers and manufacturers for some time now, and our intuition to ride this trend for fluid handling has proved correct. Indeed, the new ARO EVO 210 pump expresses all the benefits that come with such a choice, starting with the economic aspect.

Cut energy (and ecological) costs without sacrificing quality

Reducing energy consumption and consequently the associated costs is one of the main benefits provided by the ARO EVO 210 pump. Simple reasoning is enough to realise this immediately: the pneumatic system uses electricity (step 1) to generate compressed air (step 2), which activates the pump.

In the electrified version, on the other hand, electricity is used directly to start the pump, thus eliminating an expensive and potentially wasteful step, also in terms of quality.

It is often the case that the same compressor has to supply several machines at the same time and is either deficient or insufficient. A logistical challenge that can be avoided by investing in a more advanced and efficient system.

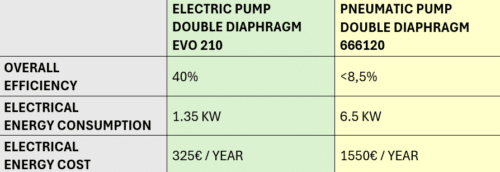

Regarding investments and profits, when comparing our electric pump with a double-diaphragm pneumatic pump, the economic advantages* of the version that does not require compressed air are clear:

*Energy saving calculated based on the following data:

- Pressure: 4 bar

- Flow: 60 and 80 lit/min

- Energy cost: 0,15€/kwh

- Hours x day: 8

- Working days: 200

Economic savings are also associated with ecologic savings: a solution that rewards sustainability and care for the environment.

Installation and maintenance are no longer a problem

The new ARO EVO 210 pump not only works perfectly, it is also easy to install and operate. The materials with which it is made offer the same guarantees of durability and resistance as a traditional pump, with the difference that in this case maintenance is simplified as much as possible. The central position of the diaphragms makes the pump structure immediately inspectable, facilitating all inspection and replacement operations.

Similarly, installation is facilitated not only by the compact dimensions of the pump – which allow it to fit into any production environment without any particular difficulty – but also by the operation itself, whereby only the essential connections need to be made to activate it. This applies whether it is a replacement or a new installation. In fact, the ARO pump can be used in numerous conditions: it can be applied outdoors or in circumstances where the electrical supply needed for a compressor is too tortuous.

Safety and control first

Among other problems often associated with pneumatic diaphragm pumps is that of possible failure or malfunctioning: a broken compressor is an important setback to deal with.

Likewise, leaks within the system can cause serious damage to the system and production in general.

To avoid this and to prevent the worst consequences, the ARO pump is equipped with electrical sensors (leak detector) that detect the presence of leaks and allow the pump to be stopped. An essential safety system to prevent liquids from reaching the motor housing and to ensure that operations are controlled at all times.

After-sales and continuous coaching

As always when it comes to Movingfluid, our role is not only that of consultants, but also of real Sfigasolver even in after-salese. An example? The provision of wear parts kits for scheduled preventive maintenance or extended warranties: all measures that serve to extend the life of products and provide coverage in the event of unforeseen events. Because what we care about is the satisfaction of those who rely on us, even in the long term.

Bad luck is in the air: why not solve it now?

We said it at the beginning: the pneumatic system works, but more and more sectors are turning to more high-performance and efficient solutions that do not involve the use of compressed air. Indeed, this is the insidious element, as it requires complex equipment and, above all, drains energy and economic resources that could be more profitably deployed. So why not opt now for a practical, reliable and mishap-proof alternative?

In addition to the 1”’ diaphragm electric pump already available – and compatible with all the processes consistent with the expected flow rate – the EVO SeriesTM 200 range will soon be completed by 2” and 3” versions, currently under development: one more opportunity that we will be proud to present to the market to respond even better to the challenges of those working with liquid handling.

You have realised that the classic diaphragm pump is no longer ideal and you want to find out all the details of the electric version offered by Movingfluid?

That’s what we’re here for!

- Airless painting [1]

- Alstom [1]

- ARO Ingersoll Rand [1]

- Atex diaphragm pump [1]

- Atex pumps [1]

- Automatic glue dilution [1]

- Automatic tissue machines [1]

- Automotive [8]

- Automotive fluid distribution [1]

- Brembo [2]

- Case History [13]

- Cast iron brakes [1]

- Centrifugal pump [1]

- Ceramic [3]

- Chemical [3]

- Chemical mixer [1]

- Chemistry [2]

- Cleaning [1]

- Cleaning industrial machinery [1]

- Dilution [1]

- Dosage [4]

- Dust [1]

- Electric diaphragm pumps [1]

- Electric double diaphragm pump [1]

- Extrusion [3]

- Finishing [1]

- Fluid for hybrid or electric vehicles [1]

- Fluid handling [4]

- Fluids [2]

- Food [1]

- Freni in ghisa [1]

- Gases [3]

- Glue [2]

- Glue Dilution [1]

- Glue dilution for paper rolling [1]

- Handling for the graphics industry [1]

- Henkel [1]

- How a centrifugal pump works [1]

- Hybrid cars [1]

- Impianti verniciatura industriale [1]

- Industrial paint booth [1]

- Industrial Painting [4]

- Industrial pump [1]

- Industrial tile painting [1]

- IVECO [1]

- Know-how [2]

- Körber Tissue [2]

- Lamborghini [2]

- Linea automatica verniciatura manicotti [1]

- Liquid paint [1]

- Liquids [6]

- LPR [1]

- Market news [4]

- Mixing chemicals [1]

- Nikola [1]

- Oenology [2]

- Oil & Gas [1]

- Packaging industry pump [1]

- Paint [2]

- Paint booth [1]

- Paper [2]

- Paper converting [1]

- Paper industry [2]

- Pneumatic powder conveying [2]

- Polcart [1]

- Powder Coating [1]

- Powder conveying [2]

- Powder conveying pumps [2]

- Powders [1]

- Printing industry pump [1]

- Pump test bench [1]

- Raw material producer [1]

- Refrigerant distribution [1]

- Refrigerant system [1]

- Refrigerant with low electrical conductivity [1]

- Saipem [1]

- Spraying [5]

- Streparava [1]

- SuperSix [1]

- Synthesis Spa [1]

- Tile [1]

- Tile painting [1]

- Tissue [3]

- Tissue converting [3]

- Tissue converting machines [1]

- Tissue glue dilution [1]

- Tissue industry glue mixing [1]

- Tissue machines [1]

- Toscotec [1]

- Trail [1]

- Transfer [7]

- Verniciatura industriale [3]

- Verniciatura industriale tubi [1]

- Verniciatura interna tubi [1]

- Verniciatura manicotti [1]

- Verniciatura tubi [1]

- Verniciatura tubi OCTG [1]

- Vortex hydra [1]

- Wood paint booth [1]